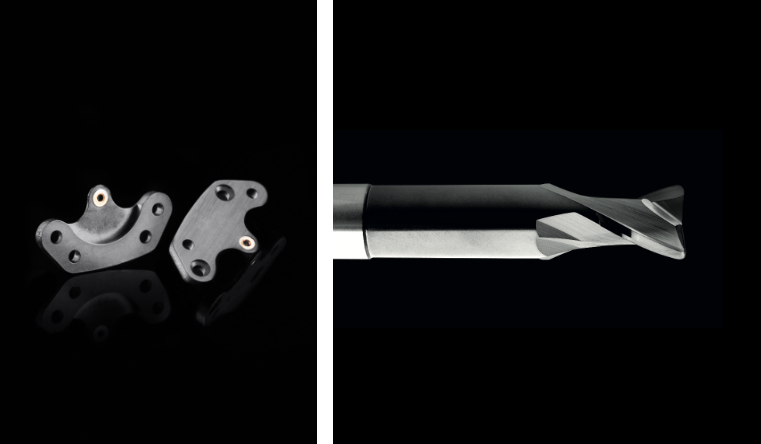

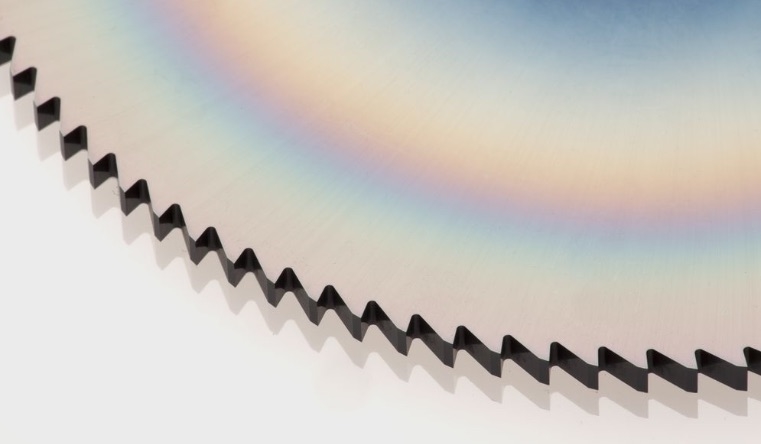

dialong® is the ta-C DLC coating deposited at a temperature below 100 °C with a standard thickness of 1 µm (customised thicknesses are available on request). The dialong® coating has a sp3 percentage (typical of natural diamond) of about 75% and a hardness of about 52 GPa (5300 HV).

| VDI abbreviation | ta-C |

| Process | PVD Arc |

| Structure | Amorphous |

| sp3 fraction [%] | 75 |

| Color | Black grey |

| Thickness | 1 µm |

| Max. operating temperature [°C] | 500 |

| Hardness [GPa] | 52 |

| Friction coefficient | 0.1 |

All data given are approximate values, depending on application, environment and test conditions. Coating hardness HIT [GPa] Measured by nano indentation according to ISO 14577. The hardness can be adapted to the application. Coefficient of friction (dry) versus steel determined by dry disc ball test with a steel ball according to ASTM G99. These values may be exceeded during run-in. Maximum service temperature [°C] These are approximate values.

High hardness: protection against abrasive wear, longer tool life, lower production costs.

High thermal stability up to 500°C: possibility of MQL and dry finishes.

Protection against adhesive wear: longer tool life and better quality of the machined component.

dialong® has proven effective on cutting tools for turning, milling, drilling, countersinking, reaming operations of non-ferrous materials such as:

- aluminum alloys up to 13% Si

- brass, copper, bronze, silver, gold, platinum

- some types of titanium

- graphite, FR4 PCBs and composite materials

- wood, plastic, epoxy resins