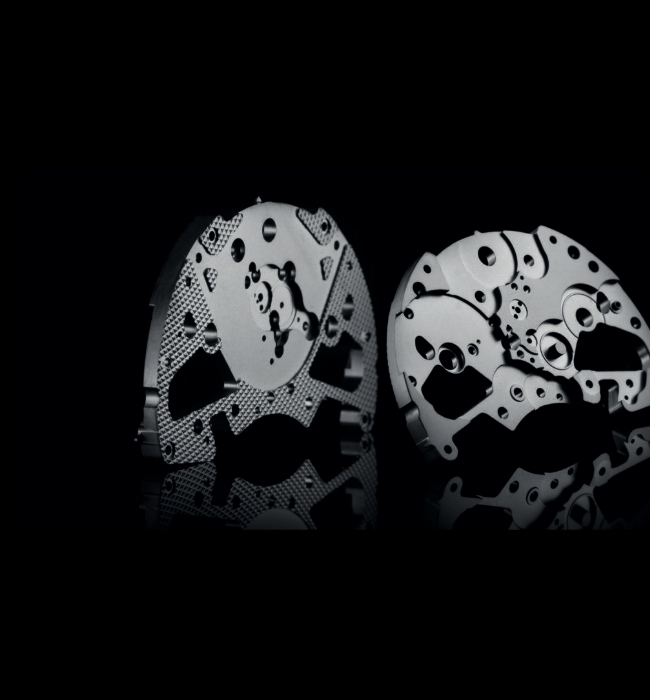

dianoir® is the ta-C DLC coating specially designed to meet the highest aesthetic and technical requirements of the watchmaking and jewellery industry. The anthracite-black colour is an optimal prerequisite for aesthetic applications and the hardness of 4500 HV guarantees high wear resistance even under harsh environmental conditions.

dianoir®

| VDI abbreviation | ta-C |

| Process | PVD Arc |

| Structure | Amorphous |

| sp3 fraction [%] | 70 |

| Color | black-grey |

| Thickness | 1 µm |

| Max. operating temperature [°C] | 500 |

| Hardness [GPa] | 44 |

| Friction coefficient | 0.1 |

All data given are approximate values, depending on application, environment and test conditions. Coating hardness HIT [GPa] Measured by nano indentation according to ISO 14577. The hardness can be adapted to the application. Coefficient of friction (dry) versus steel determined by dry disc ball test with a steel ball according to ASTM G99. These values may be exceeded during run-in. Maximum service temperature [°C] These are approximate values.

dianoir® is produced with a deposition system for ta-C DLC coatings patented by Argor-Aljba. The main advantages are:

- high wear and corrosion resistance

- uniform anthracite-black colouring

- non-toxic process and biological compatibility are optimal properties for the use of dianoir® in contact with the human skin

- special intermediate layer for perfect adhesion