Coating technologies

Argor-Aljba has 5 coating technologies: Arc PVD, filtered arc PVD (patented), sputtering PVD, PACVD and PACVD+HiPIMS (developed in-house). The ta-C DLC coatings reach a sp3 percentage of 85% while the patented dropless® technology allows us to obtain a coating that is totally free of droplets, thus guaranteeing a significantly improved performance, especially in the “industrial” sector.

Comparison with other coatings

| Type of coating | - | Hardness (HV) |

Friction coefficient |

Max. temperature of deposition [°C] |

Typical processed materials |

| Argor-Aljba dialong® | ta-C | 5’300 | 0.08 - 0.12 | <100 | Aluminium and copper alloys, precious metals, plastic, graphite, material composites |

| Titanium Nitride | Tin | 2’300 | 0.40 | <500 | Steel and stainless steel |

| Titan-Aluminium Nitride | TiAIN | 3’000 | 0.35 | <500 | Steel and stainless steel |

| Chrom Nitride | CrN | 1’800 | 0.50 | <500 | Copper |

| Zirconium nitride | ZrN | 2’500 | 0.45 | <500 | Copper and titanium |

The ta-C DLC coating structure produced by Argor-Aljba has the following properties:

- Very high hardness: up to 7000 HV0.05

- High wear resistance

- Very low friction coefficient

- Perfect adhesion, thanks to a special intermediate layer

- Inalterable with moisture

- 100% biological compatibility

- Chemical stability and corrosion resistance

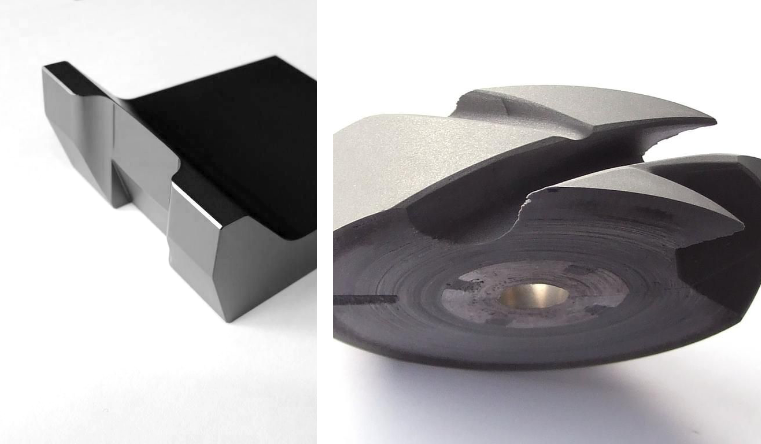

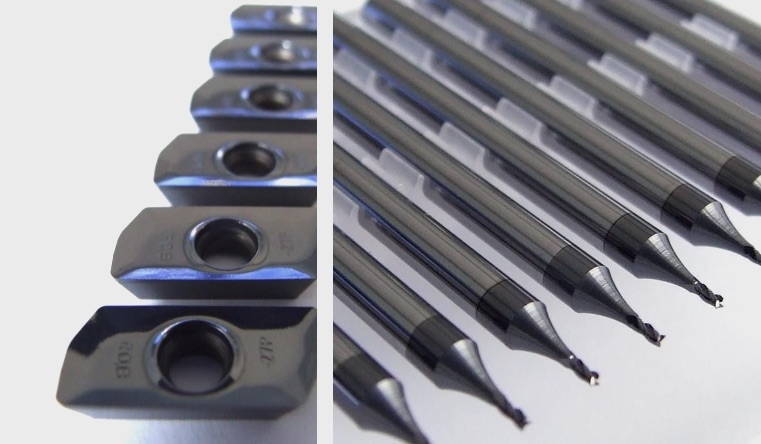

Through these properties, Argor-Aljba's coatings clearly distinguish themselves from conventional coatings. The considerably reduced friction and extreme hardness greatly increase performance, as well as the service life of tools and components, compared to conventional coatings.

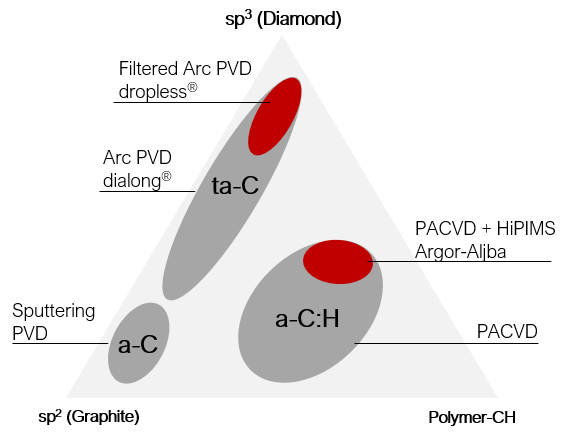

General Information on Diamond-Like Carbon (DLC) Coating

DLC coatings offer a unique combination of high hardness and low coefficient of friction, can be customised according to customer requirements and can be used in a wide range of applications in the industrial (automotive, aerospace, tooling, medical, etc.) and aesthetic/functional (watch and jewellery) sectors. Different deposition technologies make it possible to obtain DLC coatings with very different characteristics (see diagram below).

sp2 (Graphite)

Carbon with an sp2-type configuration is black in colour and not very hard. The higher the percentage of this form of carbon, the softer the layer. This type of combination is usually found among the amorphous carbon layers produced by the sputtering process.

Polymer-CH

Through the PACVD process, hydrogen is incorporated into the carbon layer. As a result, the hardness of the coating layer is reduced and resistance to increasing temperatures is very low.

sp3 (Diamond)

Carbon with an sp3 configuration is pure diamond, famous for its extreme hardness.

Arc PVD dialong®

The ta-C DLC produced with Argor-Aljba's patented Arc PVD dialong® technology has layers with a very compact and hard diamond structure. The residual graphite enhances the sliding properties.

Filtered Arc PVD dropless®

Ta-C DLC technology produced by Argor-Aljba's patented Filtered Arc Dropless® process features up to 85% diamond structure and guarantees a homogeneous coating with remarkable hardness.

PACVD + HiPIMS

The PACVD + HiPIMS coating technology developed by Argor-Aljba guarantees multilayer, very compact and polished coatings.

Decoating technologies

Argor-Aljba has chemical and PVD (in-house developed) decoating technologies that are chosen according to the DLC coating to be removed and the underlying material.

This allows us to offer the customer a complete service.

Chemical

For decoating operations, we use specific chemical solutions depending on the base material so that the DLC layer can be removed from the surface without altering the surface of the component.

Physical

For the decoating of ta-C DLC-coated components, we use the PVD process developed at Argor-Aljba that ensures optimal removal of the DLC, restoring the original surface, ready for subsequent coating.

Consultancy and expertise.

- Hardness measurement

- Roughness measurement

- Thickness measurement

- Adherence measurement

- Abrasion measurement

- SEM + EDXS

- Measurement report

- NSST corrosion measurement

- Corrosion measurement report