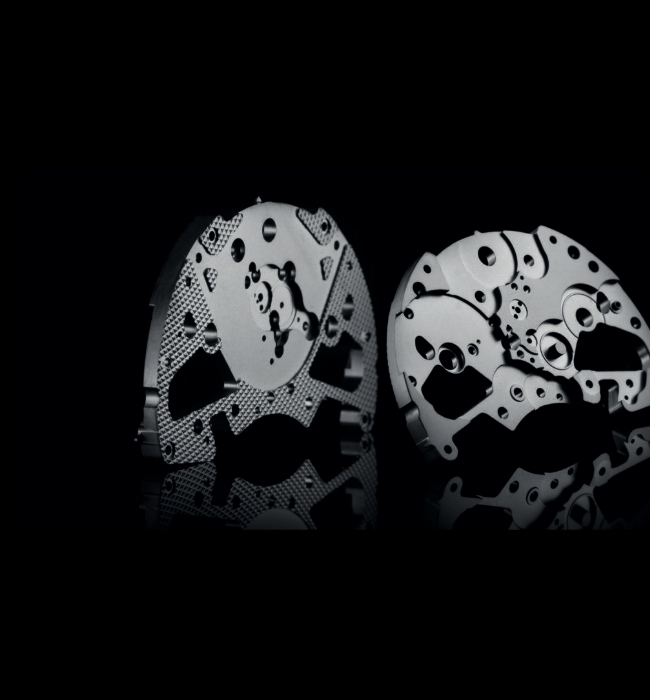

dianoir® is the ta-C DLC coating specially designed to meet the highest aesthetic and technical requirements of the watchmaking and jewellery industry. The anthracite-black colour is an optimal prerequisite for aesthetic applications and the hardness of 4500 HV guarantees high wear resistance and scratch resistance even under harsh environmental conditions. 100% Swiss made: dianoir® is made completely in Switzerland with a patented Swiss coating process.

dianoir®

| Technology | ta-C |

| Process | PVD Arc |

| Structure | Amorphous |

| sp3 content [%] | 70 |

| Color | anthracite |

| Thickness | 1 µm |

| Deposition temperature [°C] | <100 |

| Hardness [GPa] | 44 |

| Hardness HV 0.05 | 4500 |

Generic remark: all data are approximate values. These ranges, depending on geometry, substrate, and surface finish, could also vary significantly.

The values shown refer to measurements made on samples in INOX 316.

dianoir® is produced with a deposition system for ta-C DLC coatings patented by Argor-Aljba. The main advantages are:

- high wear and corrosion resistance

- uniform anthracite colouring

- non-toxic process and biological compatibility are optimal properties for the use of dianoir® in contact with the human skin

- special intermediate layer for perfect adhesion